Made according to standard

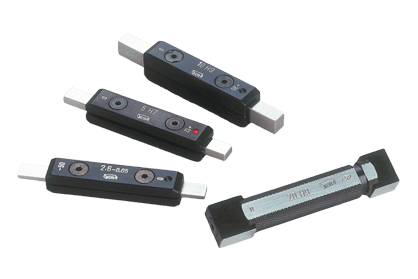

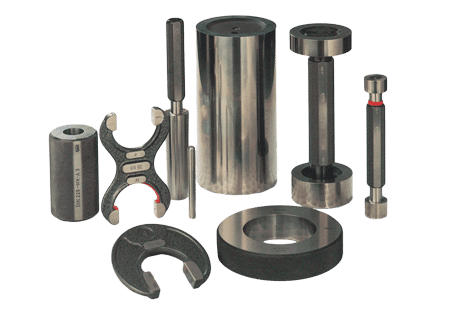

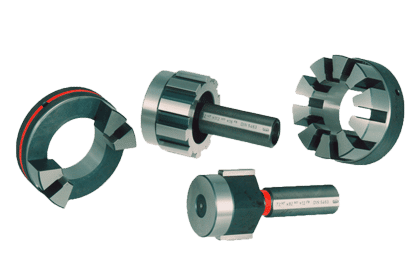

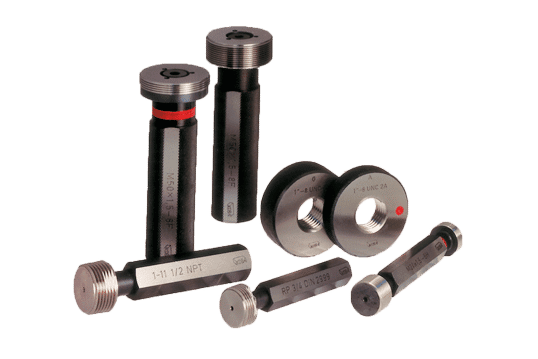

In the range of Gauges and Setting Standards KOBA offers optimal solutions for customers. This includes high quality Limit Gauges for attributive checking of work pieces as well as Setting Masters and Reference Standards for Length Measuring Comparators.

Gauges are used to check standard dimensions and are mainly used in quality assurance.

They are reference standards for previously defined dimensions and shapes.

A gauge embodies the physical dimension or form (standard).

A gauge is only used to check, not to measure. No numerical value is determined,

but only the target state (gauge) is compared with the actual state of the test specimen. Its application provides a clear statement (good or reject).

Tolerances are either found in applicable standards or are determined according to design considerations.

Gauges are usually made of hardened tool steel, while the measuring surfaces are made of carbide and are usually fine ground or lapped.

Gauges can be divided into the categories of dimension gauges, form gauges and limit gauges. A further distinction is made between plain gauges and thread gauges.