Check your coordinate measuring machines with the standards from Kolb & Baumann

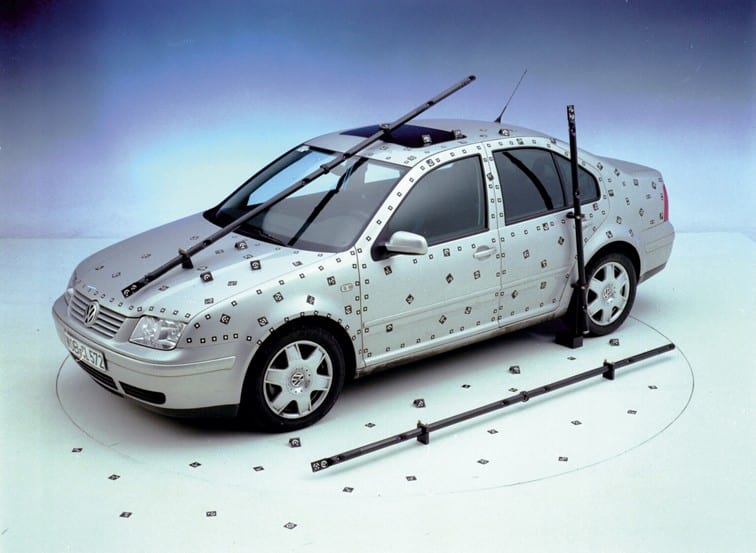

The periodic monitoring of hand-held or computer-controlled coordinate measuring machines is carried through on the basis of calibrated mechanical test bodies.

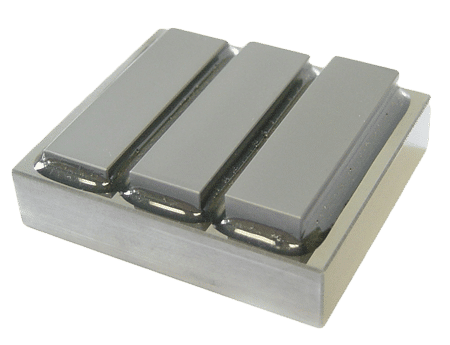

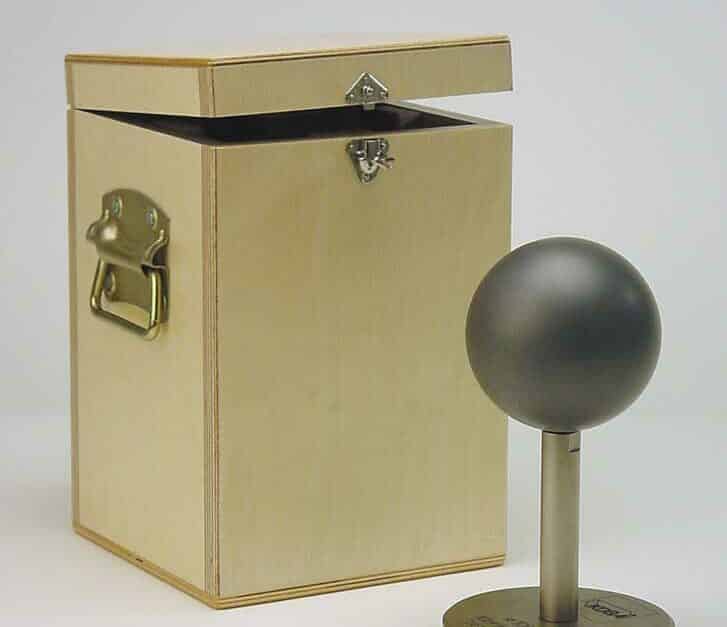

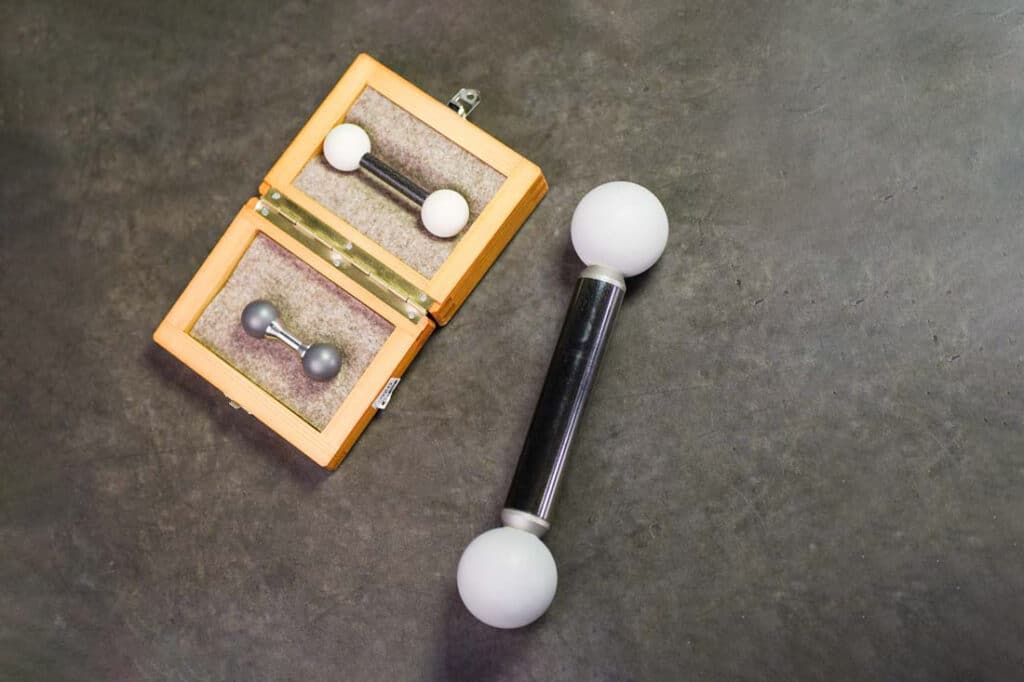

By suitable selection and combination of different test bodies such as ball, step gauge block and ball plate and their arrangement, the entire measuring volume or certain partial measuring volumes can be covered according to the typical workpiece size and the inspection can be adapted to their most important measuring task. The sequence control is uniform according to the nominal data of the test piece. Numerical and graphical evaluation is carried through with a uniform program for each type of test specimen and evaluated by qualified personnel. Summarized parameters provide an overview of the current accuracy status and long-term trends. In this way, the use of coordinate measuring machines can be optimized and their downtime minimized at low cost. Fig. 1: KOBA-check ball plate in horizontal configuration with insulating handles and probe test unit. In order to meet the increased requirements for inspection of coordinate measuring machines, Kolb & Baumann has supplemented its product range (including KOBA-step) with the KOBA-check ball plate. This embodies almost all the properties required of a test unit for monitoring CMMs