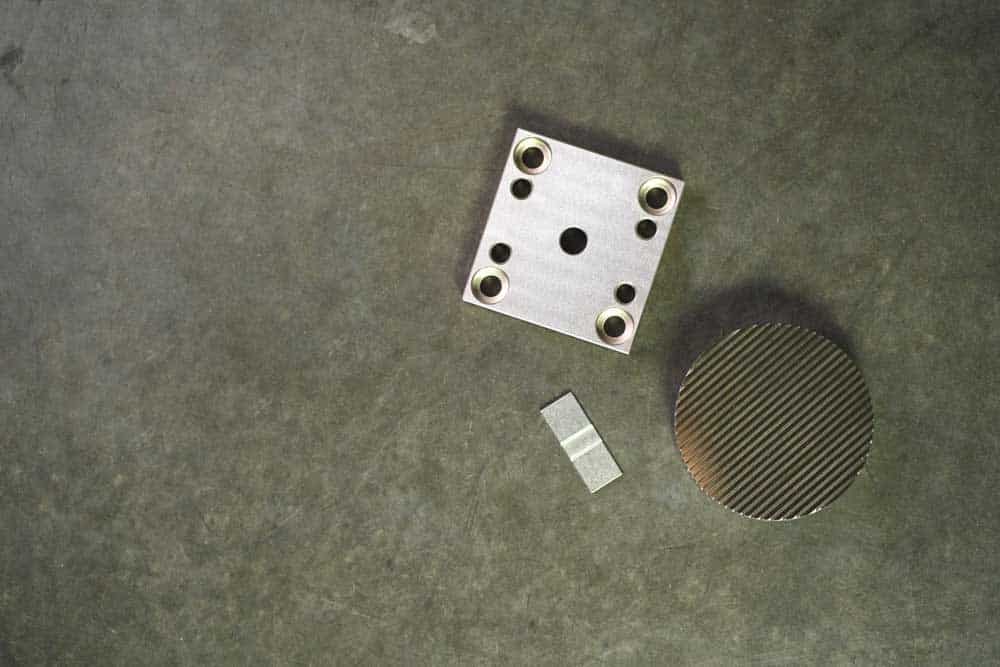

Precision Parts according to your requirements

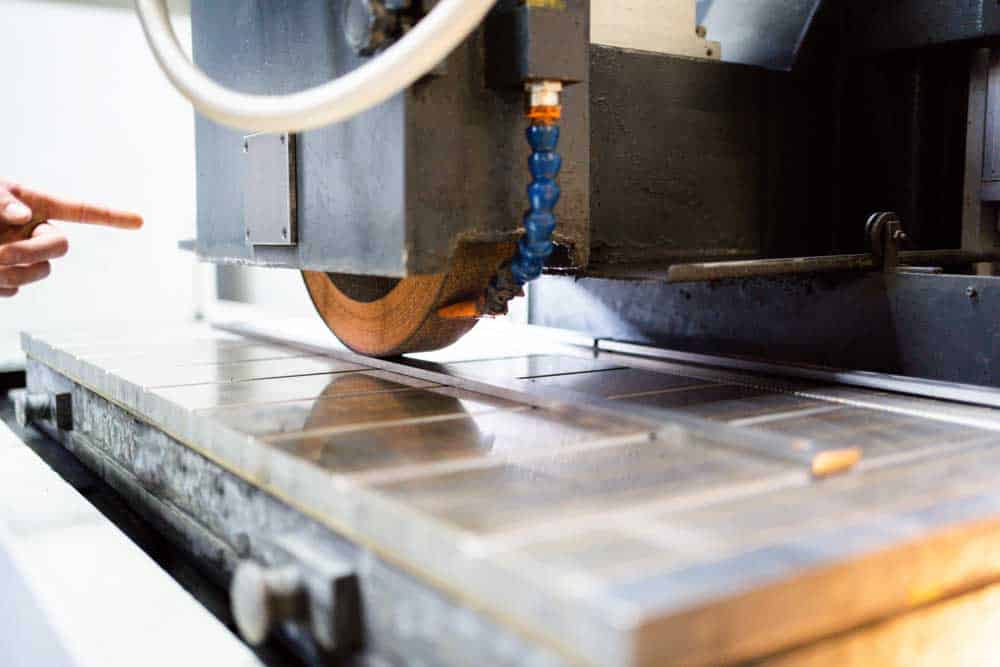

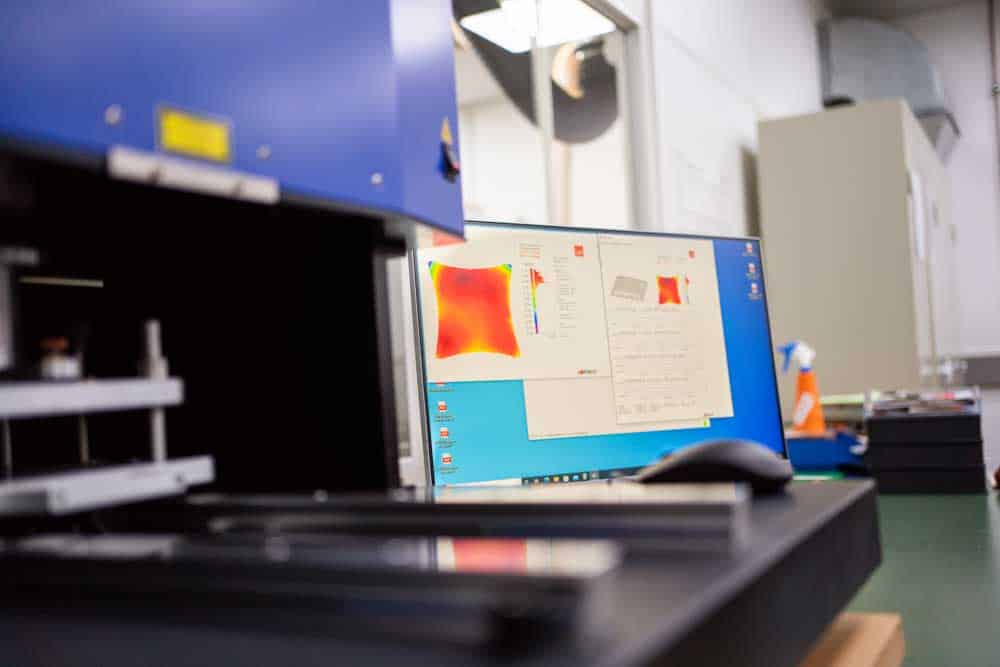

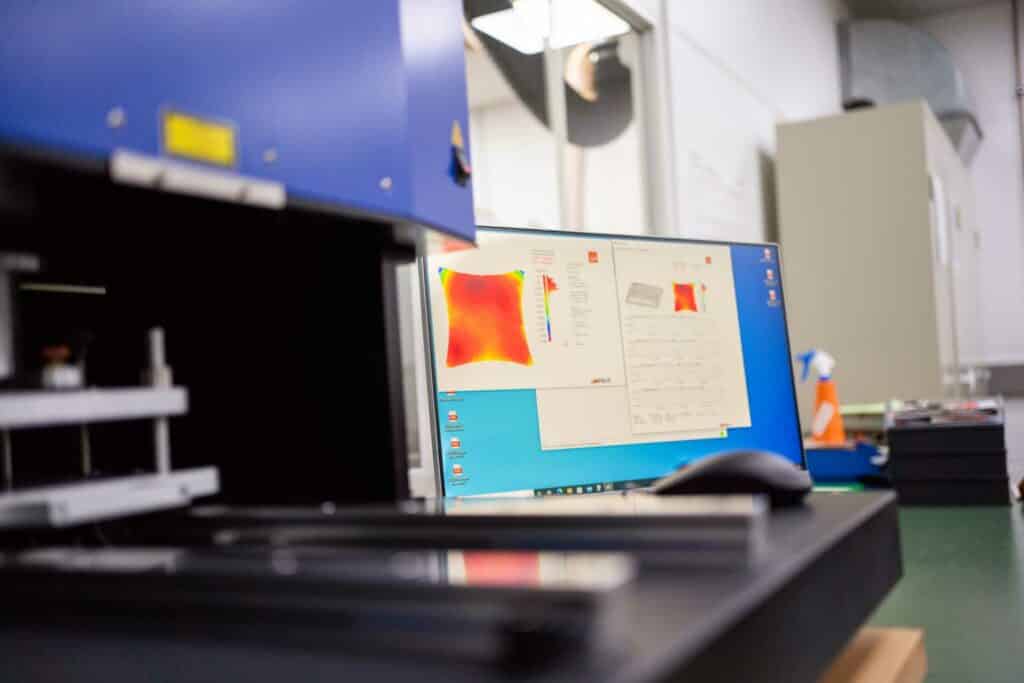

We distinguish ourselves for the complete machining of single- small series, made in Germany under the highest quality require- ments. In addition to the classic grinding processes such as fine grinding, surface grinding, face grinding, polishing and deburring by means of vibratory grinding, our surface finishing technologies also include lapping, which offers the most precise machining possibilities and represents our core competence. Our strength lies in the complete solution. We manufacture your high precision products from saw cutting to finish machining in the 0.0001 mm range with quality control