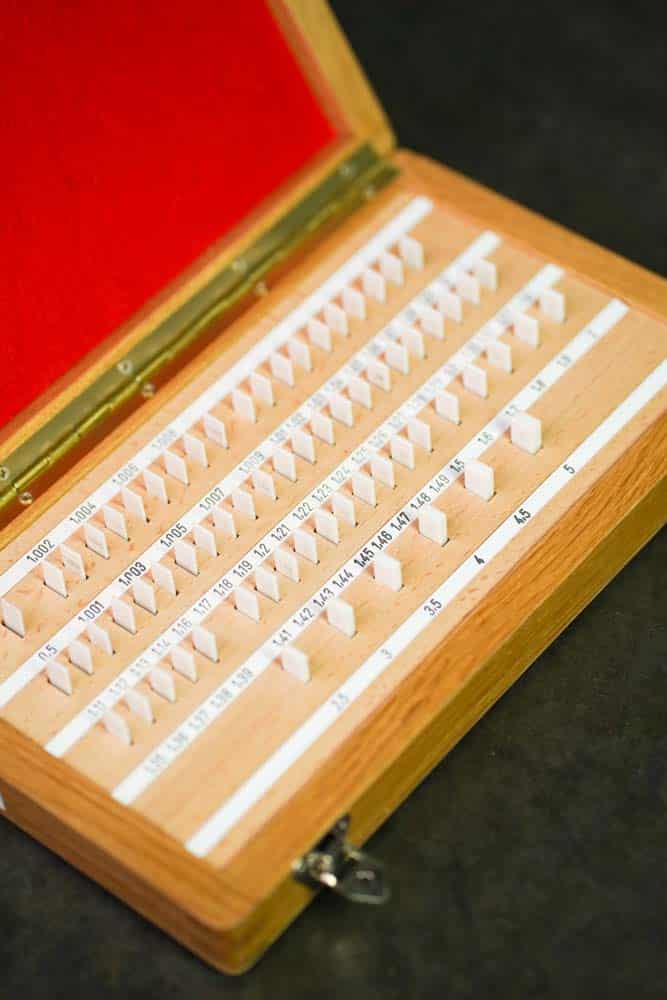

Manufactured according to DIN EN ISO 3650

Kolb & Baumann has been manufacturing gauge blocks for more than 70 years. Today we are one of the few remaining manufacturers in Germany and Europe. Contrary to the general trend, we do not market Asian products. We are proud of producing our gauge blocks exclusively at our factory work floor in Aschaffenburg. This is the only way to monitor and guarantee the outstanding quality of our products. As a calibration laboratory accredited by the Deutsche Akkreditierungsstelle GmbH (DAkkS), we have the necessary measuring equipment to ensure the high quality standard. Gauge blocks are a quality product: more than 70 years of experience and research are background. The composition and purity of the material, the aging and stabilization methods, the processing, the dimensional control, the surface quality, the wear resistance, the sensible design of the storage boxes: all these aspects are subject to ongoing critical examination at KOBA